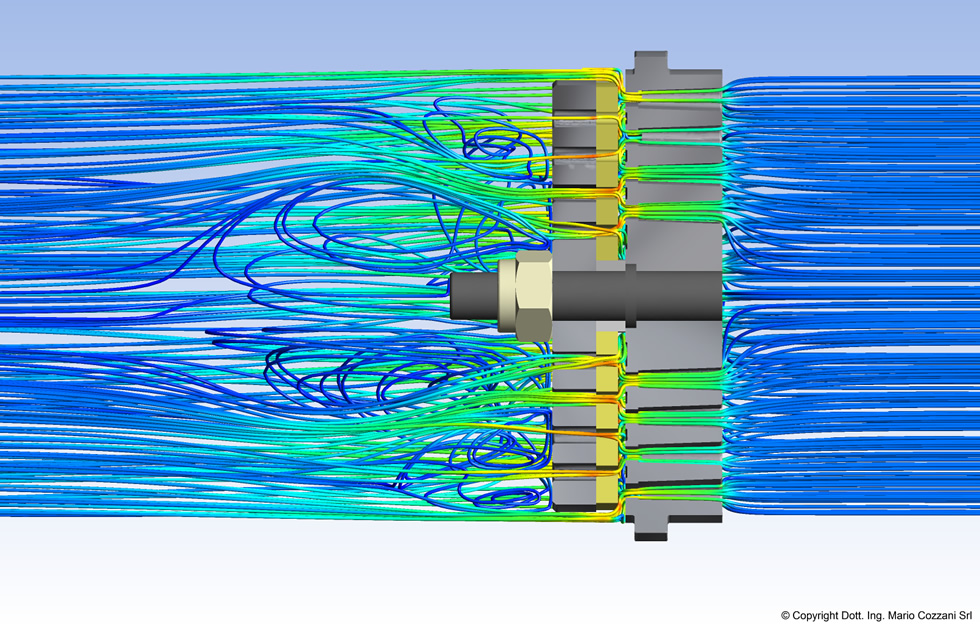

It is aso equipped with CAD 2D systems, 3D modelling systems, FEM structural analysis, an internally developed calculating program which enables to simulate and optimise the sealing elements dynamic behaviour, and a software for fluidodynamic analysis.

Thanks to the latter, we are able to calculate the valve efficiency which can also be validated on a full-scale test bench, and to simulate the interaction between the valve and cylinder assembly.

Our research is focused in improving our valves, actuators and services. New materials and valve solutions are continuosly tested to improve performances and reliability of Cozzani products. And FluxtoFlow™ stepless capacity control system is continuously improved year after year to meet more demanding specificiations. Our testing facilities include flow test bench with automatic acquistion data, reciprocating compressors, high frequency dynamometer with climatic chamber, fatigue test bench, and a shaking table with pressure equipment test.