The engineering department of Dott. Ing. Mario Cozzani s.r.l. identifies and develops custom made solutions, which are continuously customized and improved over time. The use of advanced calculating programs together with test facilities and the experience built over 75 years, enables it to design the solution that optimises performance and reliability of the products, for any kind of gas and working conditions.

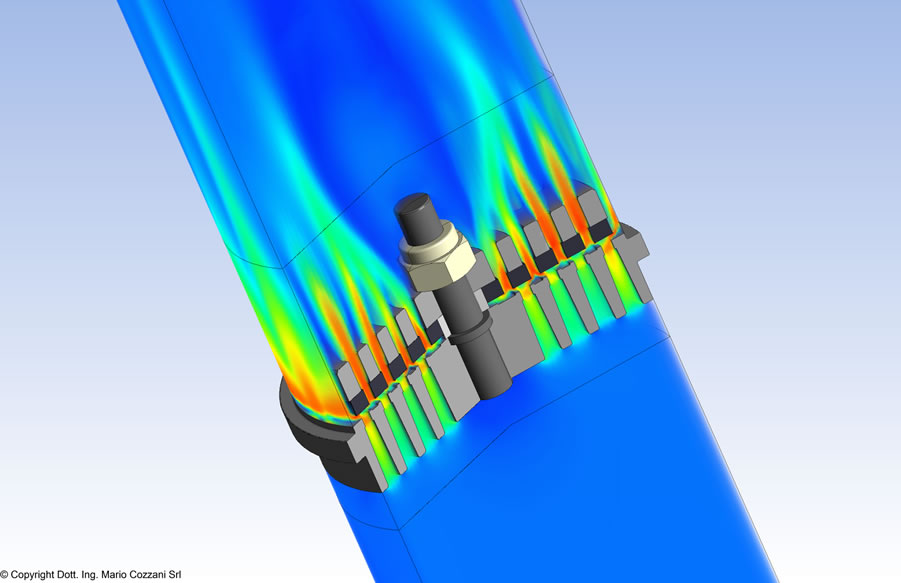

The valve design is made with the support of advanced softwares: 3D modelling systems, CFD fluidodynamic and FEM structural analysis software and valve dynamic simulators developed by Dott. Ing. Mario Cozzani s.r.l. itself. The constant research to increase compressor performance in terms of efficiency and lifetime involves the calculation of fluidodynamic efficiency of different flow passages through the valve and the valve design integrated in the cylinder. In addition to that, test bench enables full validation of the valve performances.

The engineering support that we offer to our clients includes CFD simulations of suction and discharge cylinder ducts as well as dynamic multiphase simultaneous simulations. These capabilities enable our Company to optimize the valves not only for new compressors but also for existing ones by carrying out revamping engineering in collaboration with our partners.

The size of valves changes in accordance with the applications and features required, ranging from 20mm to 600mm for suction, discharge or concentric valve types and valves are designed with safety guard or open guard, according to the requested specification. Whatever the selected type of valves and actuators, the external dimensions can always be adapted to the client needs.

The competence of designing the type of valve most suited to the specific use amongst the various available types, relies on our engineering department that develops the best technical solutions according to the compressor working conditions and complying with international norms such as API 618 and NACE MR0175 when required.

Our product are desinged to optimize the compressor working conditions and also to comply with international norme such as API 618 and NACE MR0175 if required.

Since May 2002, check valves have been designed and produced according to the European Pressure Equipment Directive (PED), 2014/68/UE, while pneumatic actuators can be designed and produced according to ATEX 2014/34/UE when requested.

Cozzani products are produced in a wide range of materials, such as carbon steel, austenitic stainless steel, martensitic stainless steel, precipitation-hardening stainless steel, special alloys (Monel®, Hastelloy®, Inconel® etc.) as well as different types of thermoplastic materials (Nylon, PTFE, PEEK™, VESPEL® etc.)