Our products are designed, engineered and manufactured to cover a wide range of applications.

They are studied and optimised in function to the compressors various working conditions, such us pressure, temperature, rotation speed, type of gas, corrosiveness, lubrication and much more.

Amongst the numerous applications carried out in our history, we mention valves for synthesis of polypropylene compressors at a pressure of 850 bar in 1965, valves which are used on compressors at a speed of 1800 r.p.m. both lubricated or oilfree, valves for chlorine compression, and valves used with corrosive gases such as H2S and HCl.

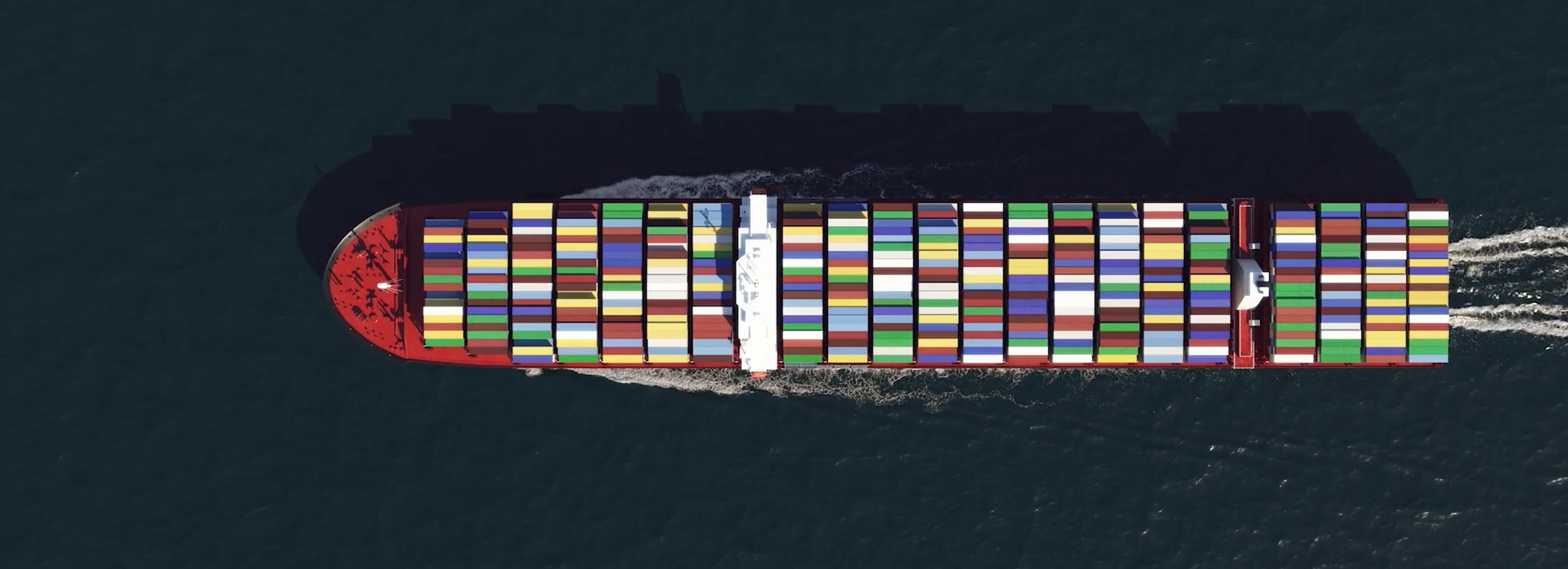

Our valves are mainly used in the chemical industry, petro-chemical, petroleum refining, co-generation, in the extraction and distribution of natural gas, LNG, biogas, biomethan, PET bottle blow moulding installations, marine, rail and medical compressors. Moreover, with the use of high pressure hydrogen, both blue or green, our valves are more and more used for heavy transport such as ships, trains, trucks and buses.